Power that moves you.

Rigid carbon composite panels for things that move.

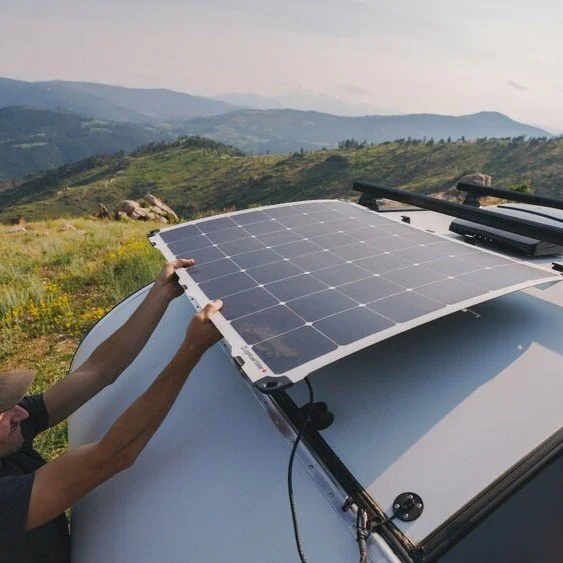

We provide ultralight, rigid solar panels with incredibly convenient design.

Our rugged carbon fiber solar panels are designed to seamlessly integrate with trailers, sailboats, vehicles, and more. If it moves, we can power it - with panels that are ultralight, efficient, and uncompromising in their strength.

Our panels

-

seaLeaf

Lightweight, rigid, rail-mounted solar panels for boats.

-

dropLeaf

Deployable, rigid, lightweight solar for small trailers.

-

gLeaf

Rigid and lightweight fixed mount solar to power any mobile project.

Just 5 pounds and 9 millimeters thin.

LightLeaf Solar panels are engineered to enhance your outdoor experience. Our leading-edge technology combines rigidity and functionality, with an unbending foundation of carbon fiber strengthening every panel without any sacrifice.

From our customers

Learn more about our solar panels.

-

Aerospace-style carbon/foam sandwich construction makes our panels stiff and strong. This allows clean and versatile mounting, and protects the monocrystalline cells from flexing and cracking.

-

Our panels are 1/4 the weight of standard glass panels and just 8mm thin. They are a breeze to haul around, weighing a mere 5 pounds.

-

Thick, tough, scratch-resistant polycarbonate and carbon/foam construction stands up to abuse. LightLeaf Solar panels are built to withstand anything from harsh winters to rough seas.

-

Our solar panels are designed and manufactured in Canada, using quality materials sourced from throughout North America.

LET’S GET SOCIAL!

Frequently asked questions.

-

gLeaf (General use)

This is our general (g=general) panel. These panels are manufactured without any clamps, hardware, or kickstands. It is a general panel made for mounting to a fixed surface. Examples; RV roof, motorboat roof, sailboat sunshades, metal structures, etc... Anywhere you want a fixed panel. In order to facilitate unique mounting options we have also created various "fit-kits".

DropLeaf (Trailer usage)

The dropLeaf has unique anchoring system specifically designed for campers. It comes with a kickstand (or two depending on size). This allows campers to be able to detach the panel from their trailer and place it in the sun. Often campers like to park in shaded areas and fixed panels don't work for them. The deployability of the dropLeaf has made these panels very desirable.

SeaLeaf (Marine usage)

The seaLeaf (even though it looks the same as the gLeaf) is significantly different. The seaLeaf has hard point foam inserts, and much more reinforcing in the lamination schedule. The seaLeaf is reinforced so that it can support itself by two cantilever clamps. These clamps are manufactured for mounting on rails for easy installation, as well as, easily change the angle of the panel so that it better faces the sun for optimum charge. These clamps come in three different diameters 7/8", 1" and 1.25". These sizes were chosen as they fit the railing system around most sailing yachts. -

The possibilities are endless. A single 110W solar panel can produce approximately 600 W-hrs of electricity during a single, central North-American, sunny day. It can produce the power required for a small trailer, including lighting, device charging, a compression-style refrigerator, and miscellaneous loads. However, it would not be enough to operate air-conditioning, or heaters for a long period of time.

In addition, it could charge a 1 kWh portable power station in approximately 1.5 days from fully discharged.

-

These panels are the best on the market at 24.9% efficient. The most efficient cells available are SunPower Maxeon monocrystalline cells and that is what we use. Cheaper panels are about ~21% efficient.

-

The performance is largely influenced by the wiring configuration. Typically, an array of cells is wired in series. This means if one cell is shaded, the entire array's performance is affected similarly. Unlike other panels, our junction boxes incorporate 2 Schottky bypass diodes, effectively dividing these cells into 3 separate arrays, meaning if one cell is shaded, it will only effect 1 of 3 arrays, instead of the entire panel. This setup enhances both charging efficiency and circuit protection.

Additionally, our panels are exceptionally lightweight and include a convenient kickstand for easy adjustment. In shaded conditions, simply detach the panel and position it in direct sunlight for optimal performance.

-

Our panels can be connected either in series or parallel. Either method has their pros and cons dependent on the mounting location and the application. It is not easy to make a blanket statement to indicate which is the best. We strongly recommend connecting each individual panel to a high quality MPPT solar charge controller with boost function.

-

Our panels do not come with controllers, but an MPPT solar charge controller is required. These protect and efficiently charge your battery system. The solar panel should never be connected directly to a 12V battery.

-

We are partnered with many trailer manufacturers who provide LightLeaf Solar panels as an option. Contact them first, as they will have your trailer's exact measurements and specifications. Follow the link here to see a list of trailer manufacturers we work with. Alternatively, we supply a standard model - the standard dropLeaf - with a generalized curvature that fits many trailers.

-

You can test the functionality of your solar panel with a basic multimeter by measuring two parameters – open circuit voltage (Voc) and short-circuit current (Isc).

For these tests, you need to place the panel pointing towards the sun on a sunny afternoon.

To measure Voc, set your multimeter to "DC volts" (50V range) and connect the leads to the output cable from the panel. It should match the specifications listed in the serial number label on the back of the panel.

To measure Isc, set the multimeter to "DC amps" (10A range). Again, connect leads to the output. The current should match the specification.

Because of variability in the sun, these readings can vary from the values listed, but should be within 20%.

-

The curve is a unique defining feature of LightLeaf Solar panels. The curve adds strength and rigidity to the panel. Panels without any curve tend to overheat and become inefficient because there is no cooling underneath. In addition, pasting flat panels to a flat surface can become a major challenge if they need to be replaced and/or maintained. However, there can be some variance with the amount of curve. Typically, they are installed with the curve on flat surfaces. Flat panels may be custom-ordered.

-

There is no power advantage or disadvantage with the amount of curve we use.

-

The curve really helps with preventing dust accumulation. It also allows for the panels to get a great clean and rinse in rain.

-

Our solar panels are fully sealed and waterproof. The outward-facing surface is a polycarbonate front sheet, the back is carbon fiber with a waterproof junction box, and the edge is protected by rubber. These materials are all pretty durable but can also react to certain chemicals found in some cleaning products. For example, avoid using acetone, lacquer thinner, harsh cleaners, abrasive cleaners, and loctite thread locker.

The best way to clean them in-depth is to give them a good hosing down. If you have a smudge (e.g. Bird poop) you can apply some mild dish soap with warm water and clean off with a microfiber cloth.

-

Our polycarbonate front sheet is very durable and resistant. Under this layer of polycarbonate we use Sabic HP12W, a proven UV treated sheet which will prevent hazing. One of our trailer partners use our panels as a window rock guard, which is a testament to the durability of the panel's surface.

-

We don't build them to be walked on. Some customers have done this but we don't encourage it. These panels can comfortably support 80lbs.